1.2343 ESU

Steel Glossary

1.2343ESU H 11/BH 11 ESR

Hot work steel for the production of highly stressed hot work tools, warm forging tools, die-casting tools, hot shear blades, and forming dies.

You can obtain 1.2343 ESU as VarioPlan and EcoPlan.

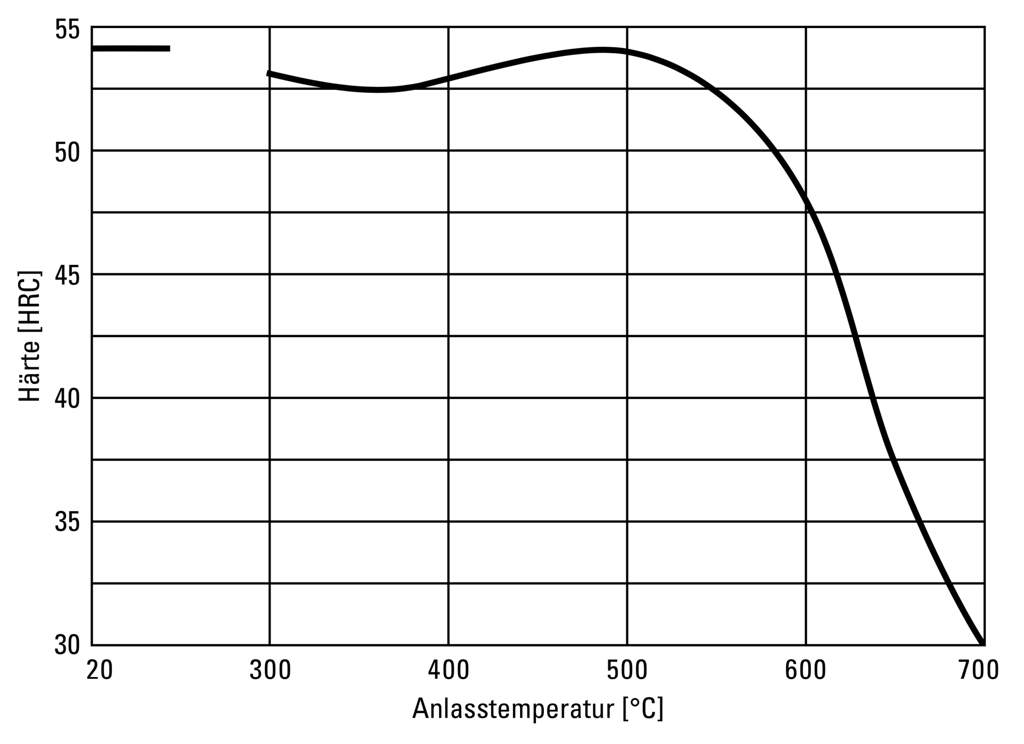

Tempering Diagram

Hardening temperature: 1020°C, Cross-Sectional Sample: Square 50 mm

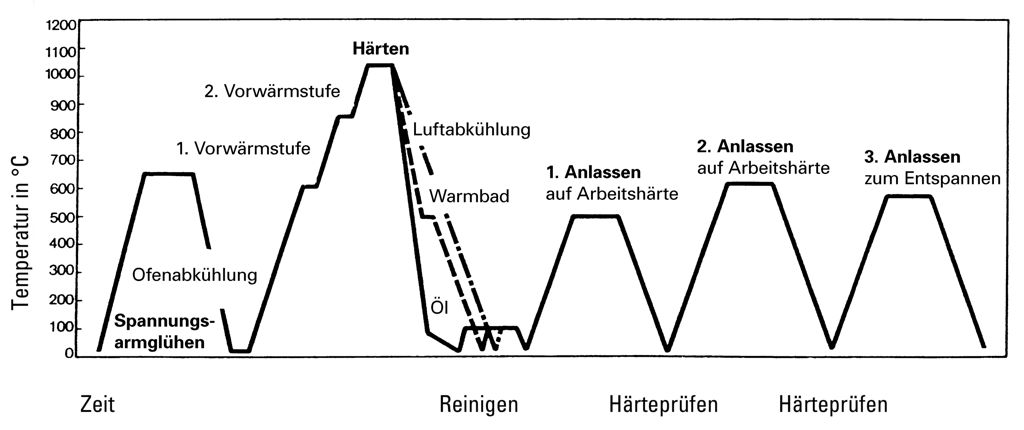

Heat Treatment Schedule

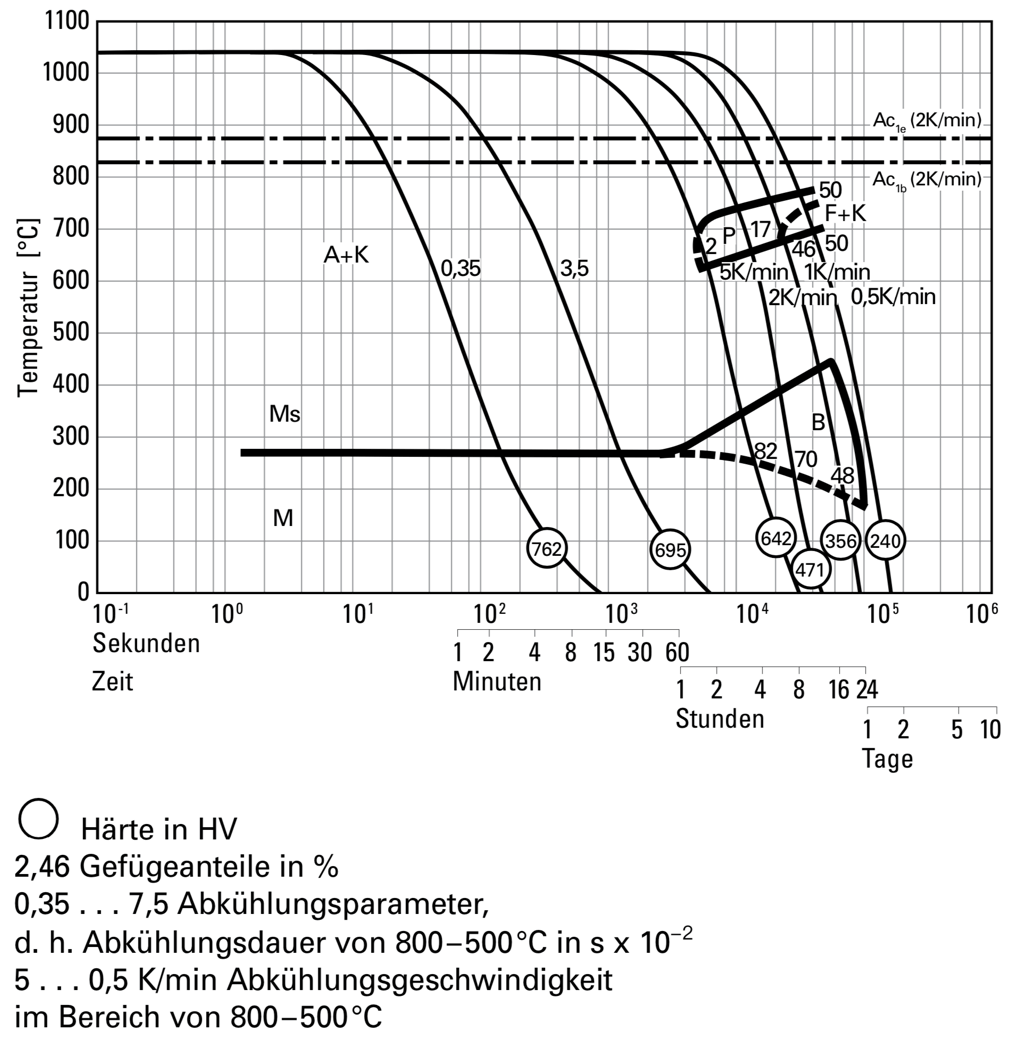

Continuous Cooling Transformation Diagram

Austenitization Temperature: 1080°C, Holding Time: 15 Minutes

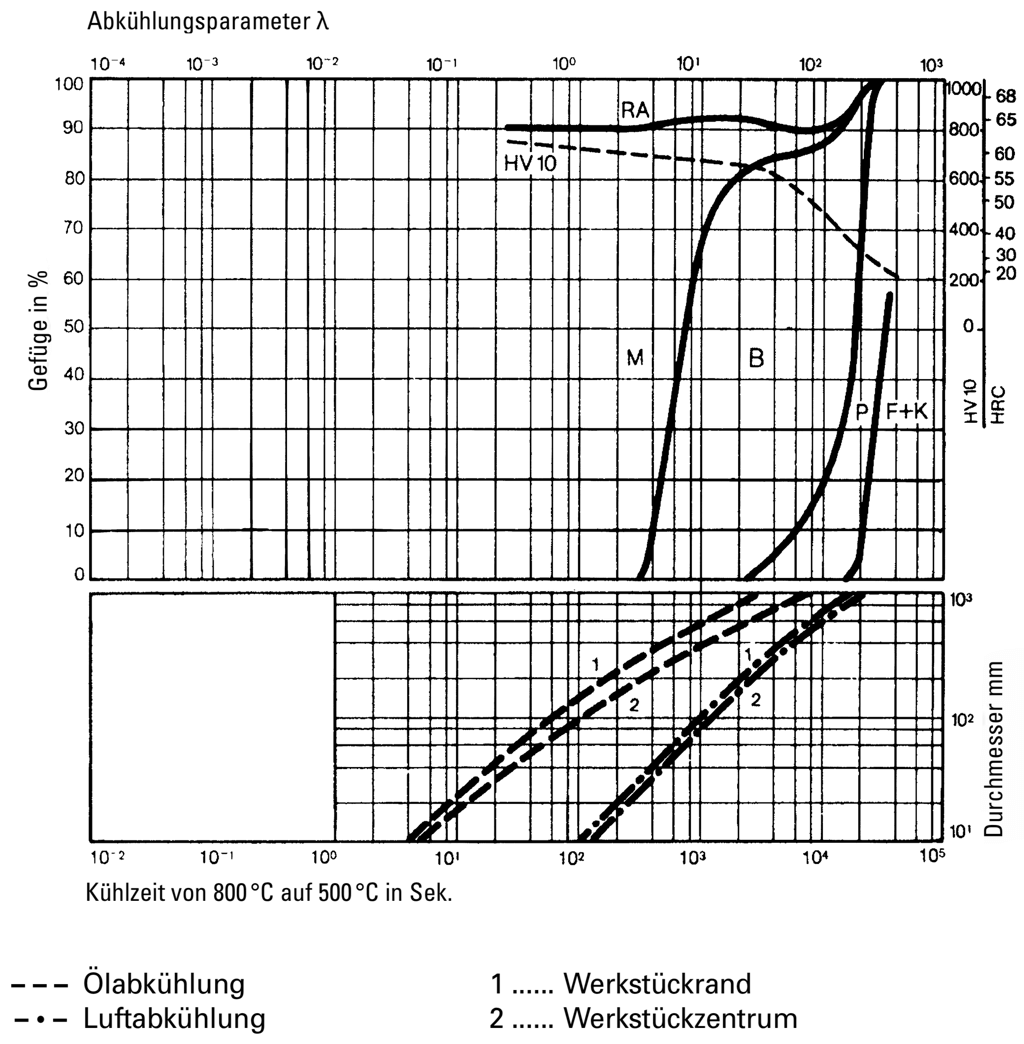

Microstructure Phase Diagram

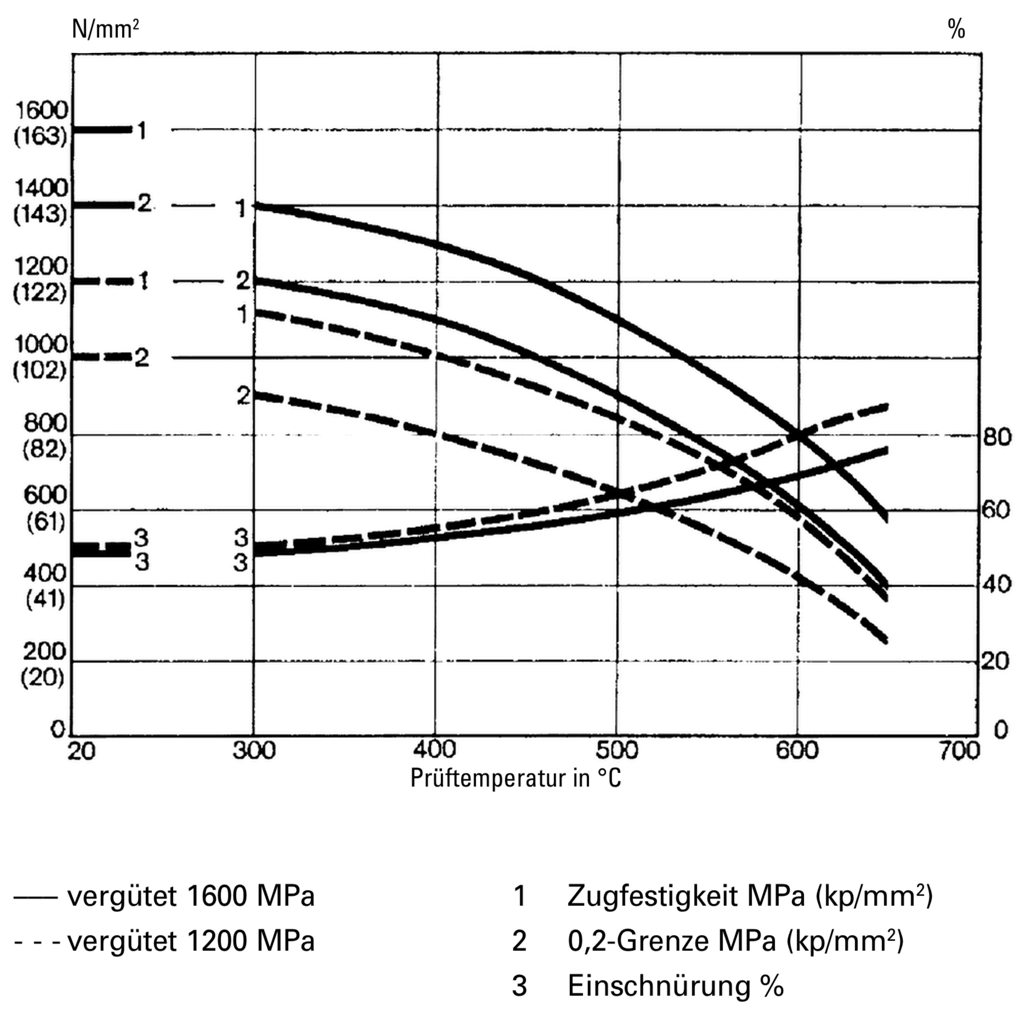

High-Temperature Strength Diagram

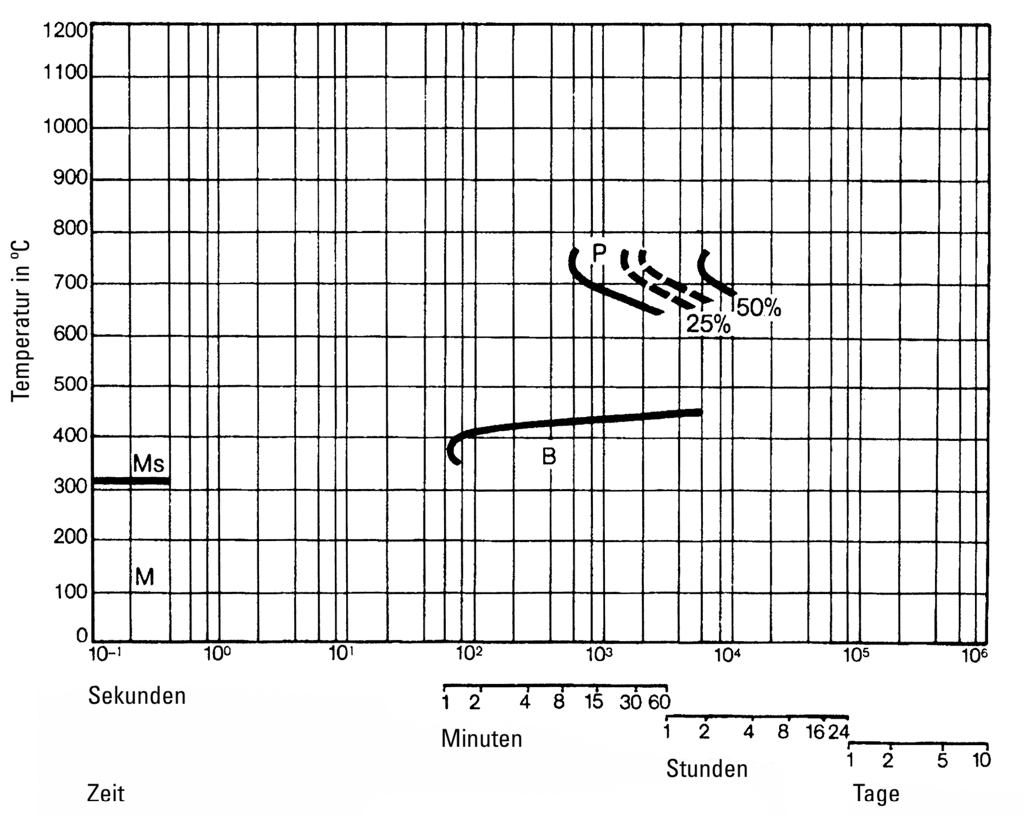

Isothermal Time-Temperature-Transformation Diagram

Austenitization Temperature: 1030°C, Holding Time: 15 Minutes

Attention please!

Some features of our webshop are not supported by your current browser version.

We recommend updating your browser or using a different browser.