Steel Glossary

1.2767 45 NiCrMo 16

AFNOR 435 NCD 5

| C | Si | Mn | Cr | Mo | Ni | |

|---|---|---|---|---|---|---|

| max. | 0.5 | 0.4 | 0.5 | 1.5 | 0.35 | 4.3 |

| min. | 0.4 | 0.1 | 0.2 | 1.2 | 0.15 | 3.8 |

Tool steel for heavily stressed solid forging tools, cold heading tools, cold shear blades, and for the production of plastic molds.

You can obtain this material from us as precision flat steel (standard and special dimensions), VarioPlan, VarioRond, and as raw material cut to size.

You can also get 1.2767 from us as a finished machined part, customized according to your specifications.

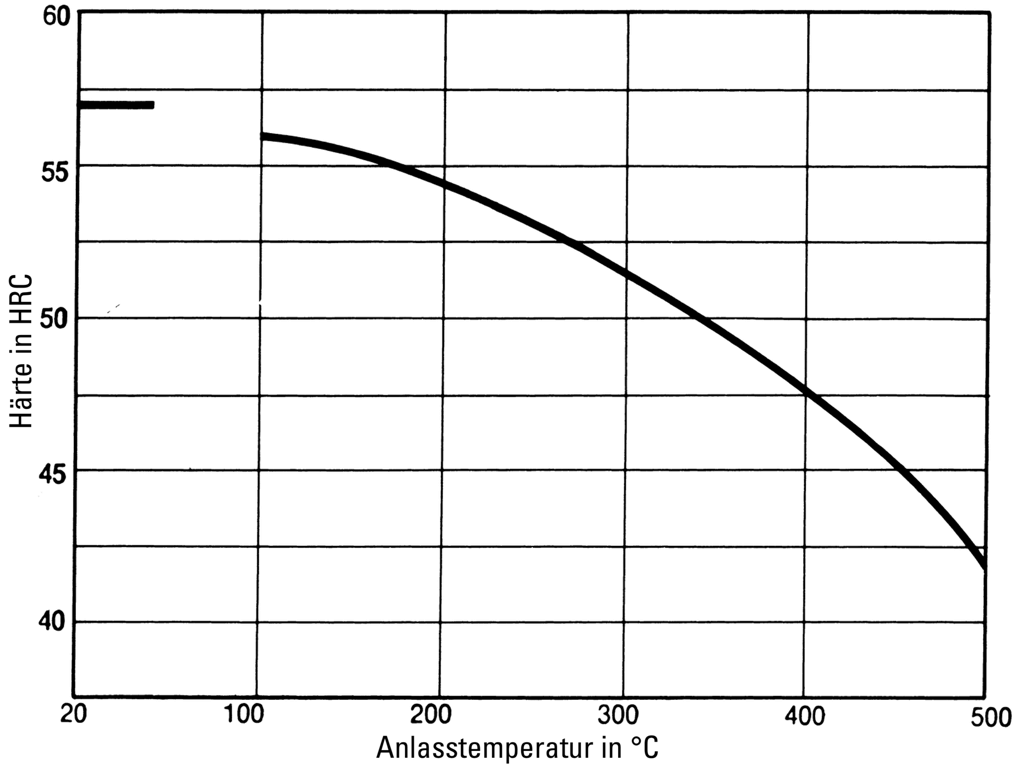

Tempering Diagramm

Hardening Temperature: 850°C, Cross-Sectional Sample: Square 20mm

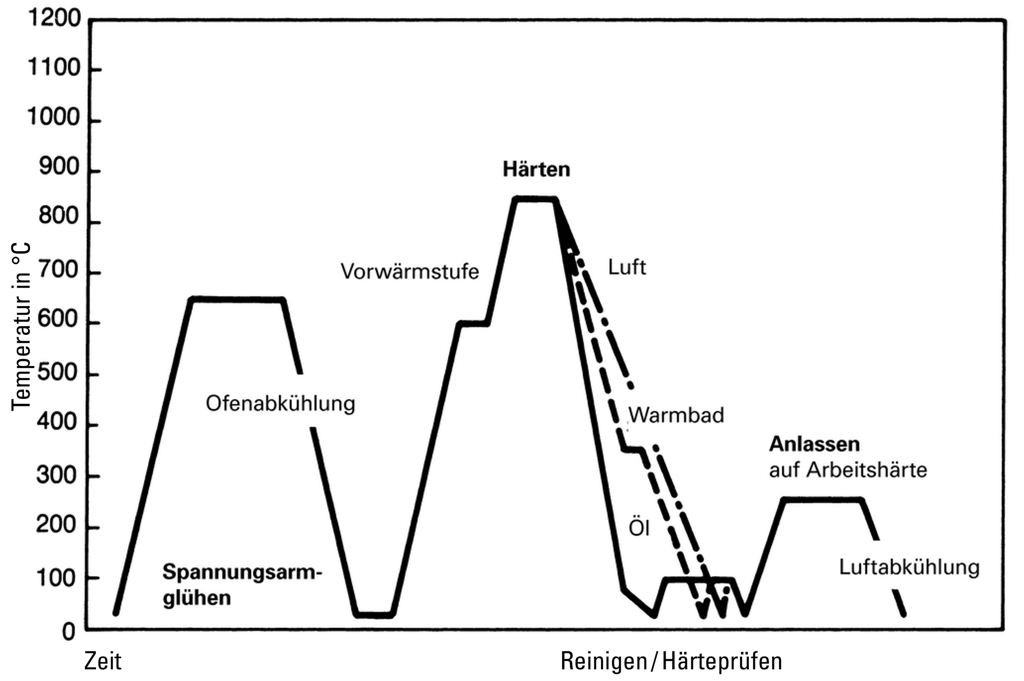

Heat Treatment Schedule

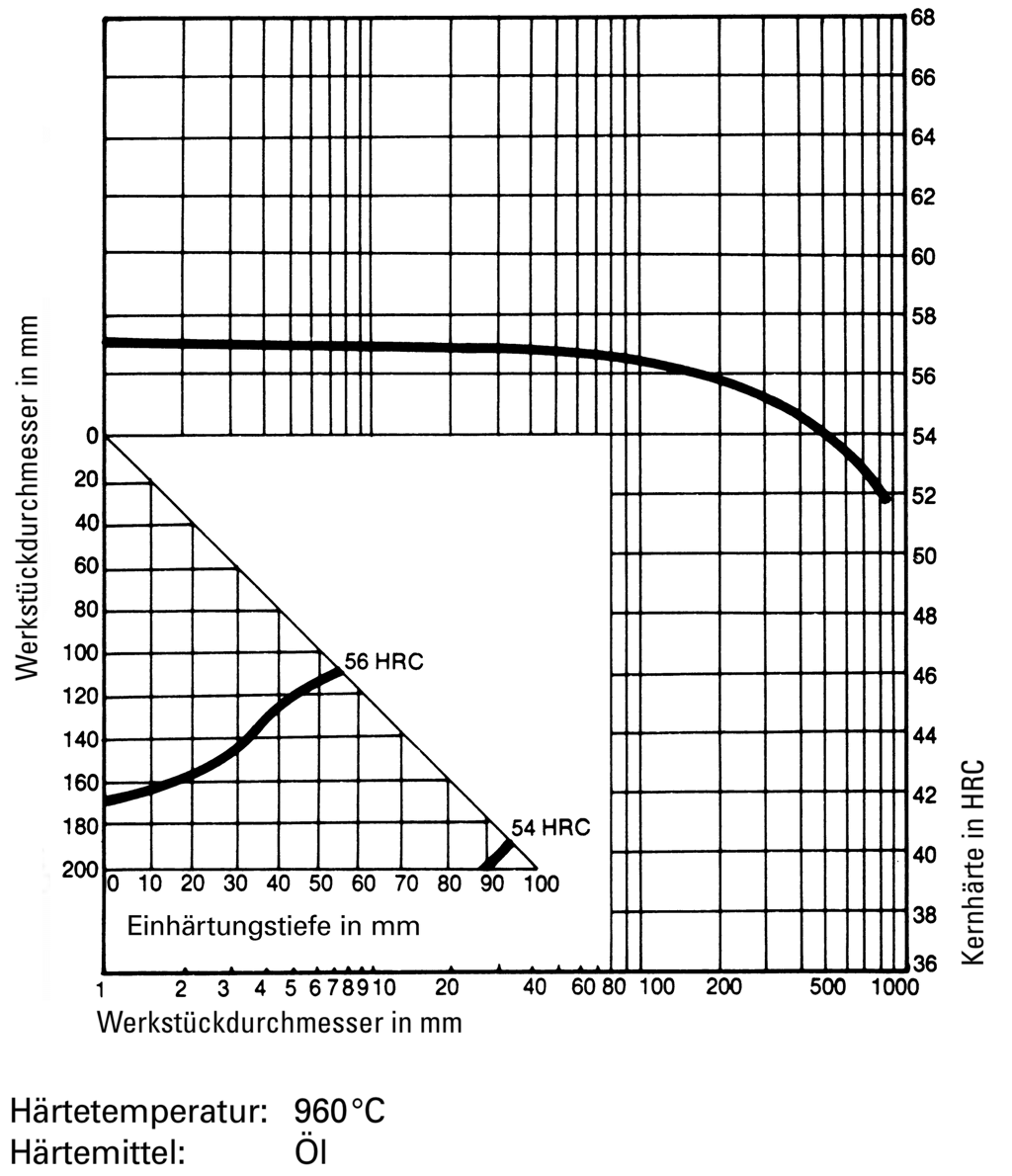

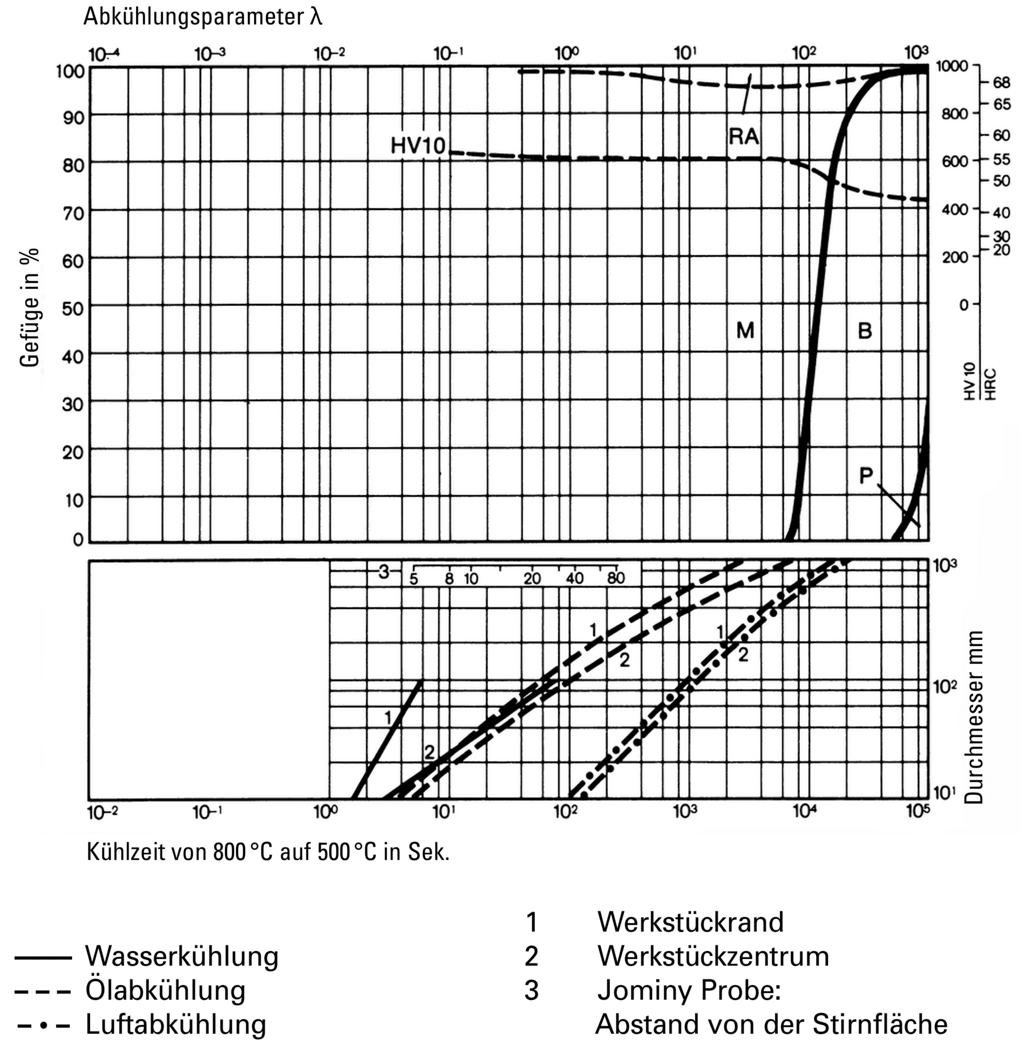

Dependency of Core Hardness and Effective Hardening Depth on Workpiece Diameter.

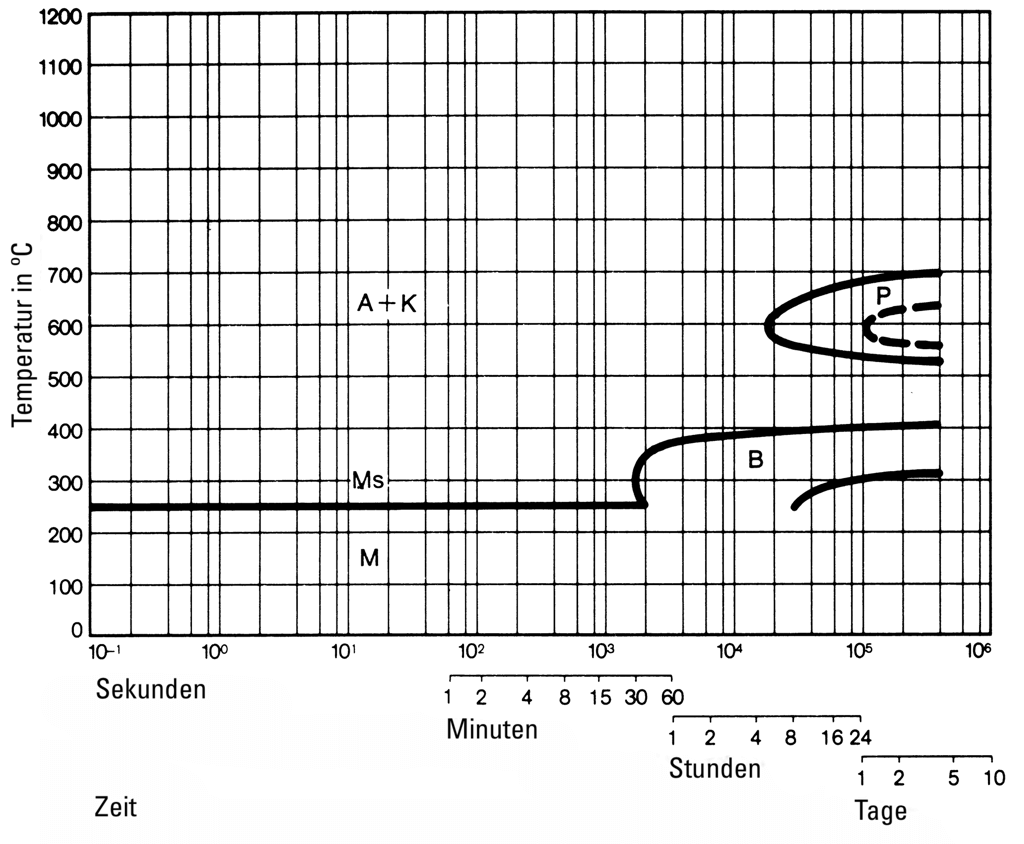

Isothermal Time Temperature Transformation Diagram

Austenitization Temperature: 840°C, Holding Time: 15 Minutes

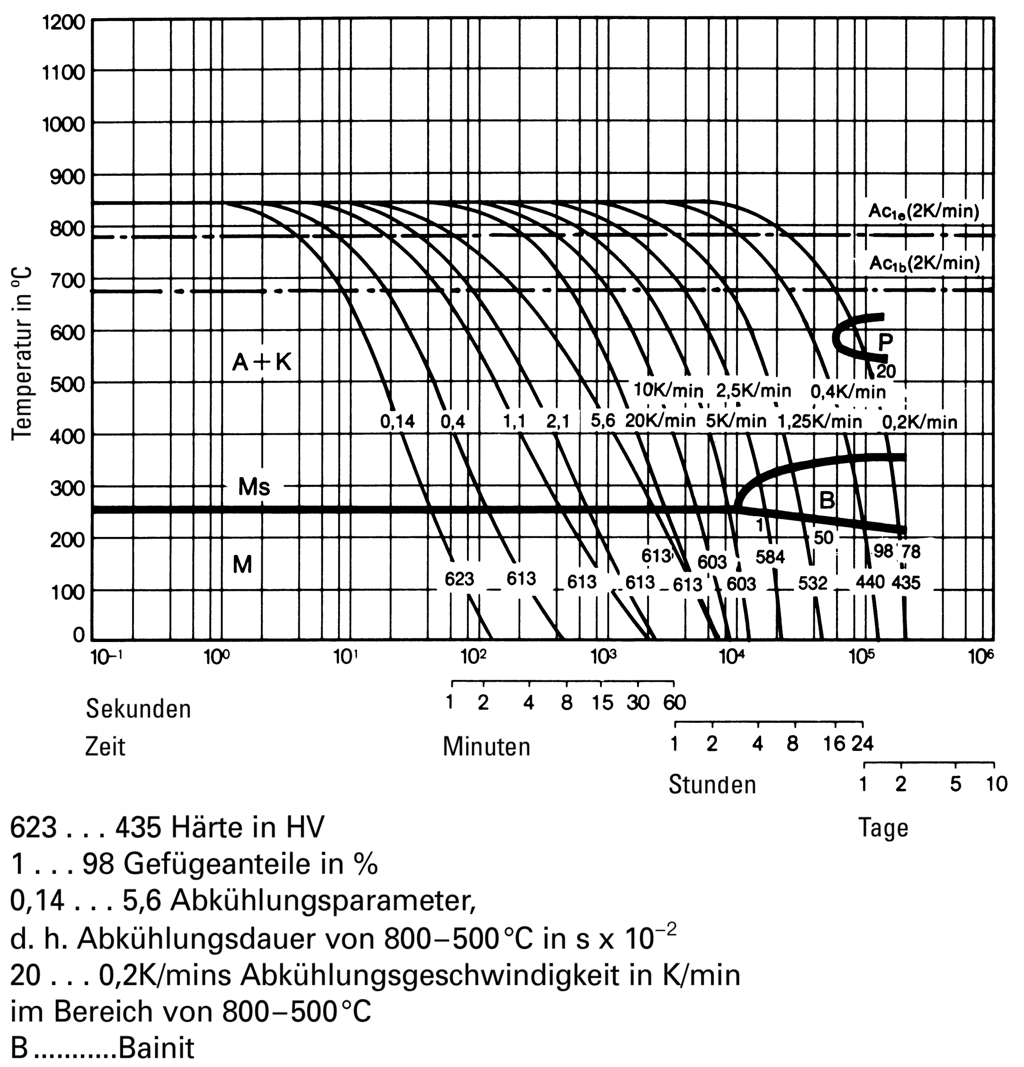

Continuous Cooling Transformation Diagram

Austenitization Temperature: 840°C, Holding Time: 15 Minutes

Microstructure Phase Diagram

Attention please!

Some features of our webshop are not supported by your current browser version.

We recommend updating your browser or using a different browser.