Steel Glossary

1.2842 O 2/BO 2

AISI O2, BS BO2, AFNOR 90 M V 8

| C | Si | Mn | Cr | V | |

|---|---|---|---|---|---|

| max. | 0.95 | 0.40 | 2.20 | 0.50 | 0.20 |

| min. | 0.85 | 0.10 | 1.80 | 0.20 | 0.05 |

Cold work tool steel for the production of tools, gauges, fixtures, templates, guide rails, and components of all kinds.

You can obtain this material from us as precision flat steel (standard and special dimensions), VarioPlan, VarioRond, and as raw material cut to size.

You can also get 1.2842 from us, tailored to your specifications, as a standard material for machine parts and hardened guide rails up to 40mm thickness.

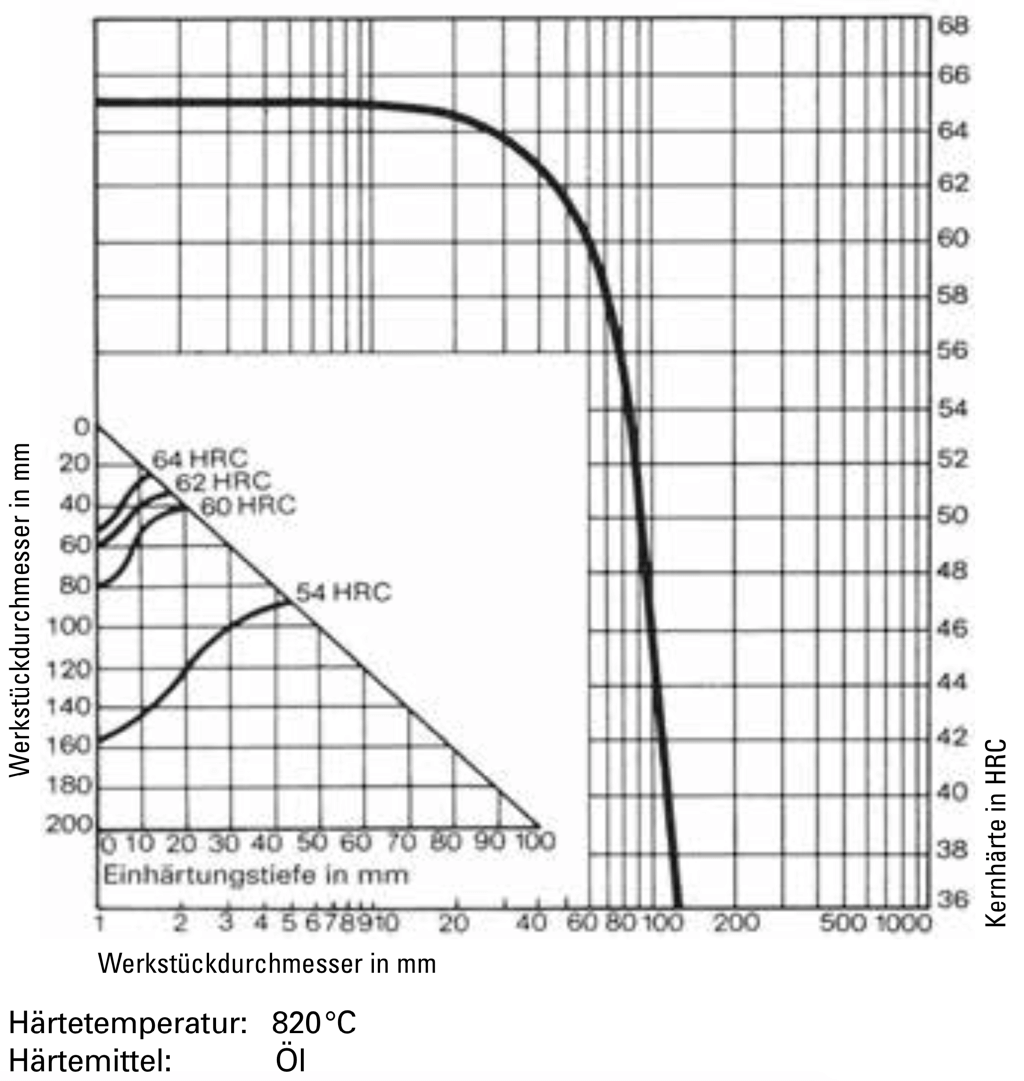

When heat-treating 1.2842, it is essential to consider that it is a through-hardening steel that experiences a volume change of approximately 1‰ during the process but exhibits very low distortion. Workpiece cross-sections over 40mm thickness might result in hardness levels lower than 58 – 62 HRC. For larger cross-sections of guide rails, we recommend 1.2363 or 1.2379, and for wear parts, consider 1.2436. For untreated components, we suggest Toolox 33: more cost-effective despite higher strength! The machinability is good and trouble-free.

The risk of cracks during repair welding exists, as is generally the case with tool steels.

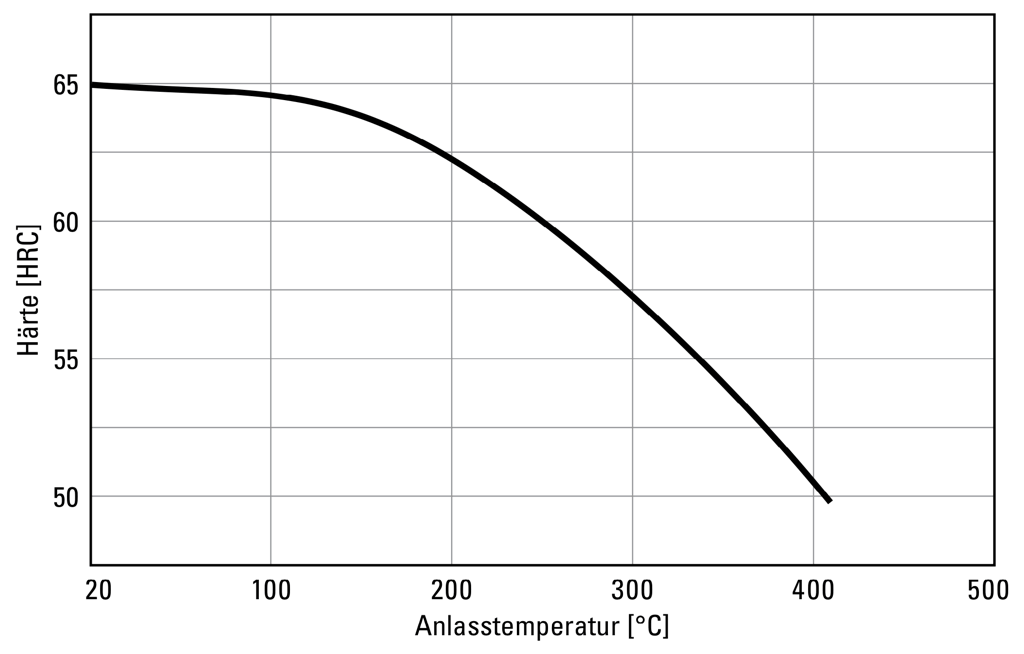

Tempering Diagramm

Hardening Temperature: 810°C, Cross-Sectional Sample: Square 20mm

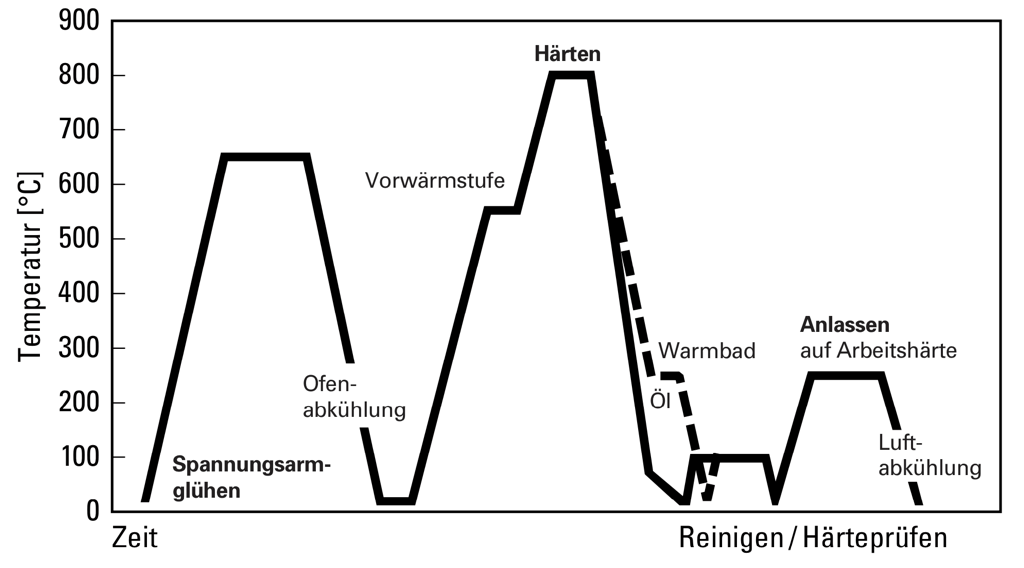

Heat Treatment Schedule

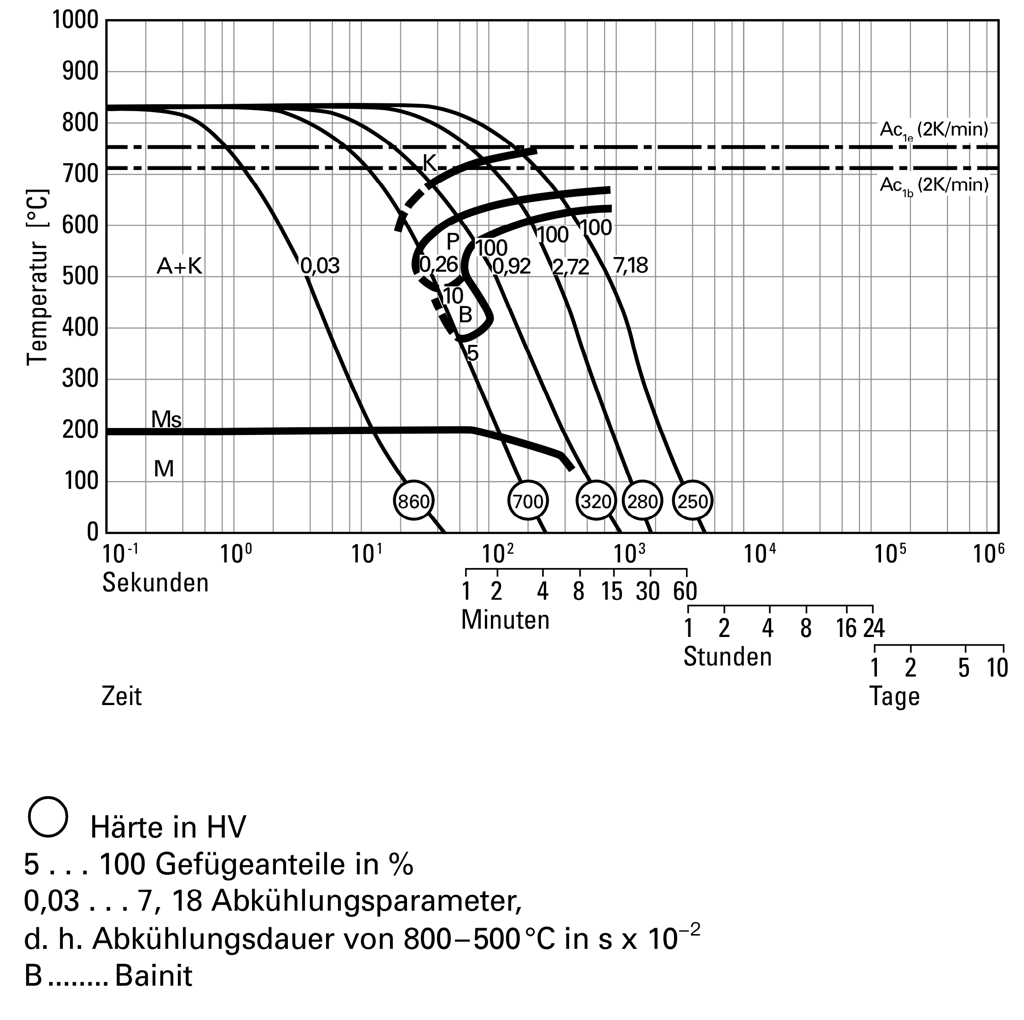

Continuous Cooling Transformation Diagram

Austenitization Temperature: 820°C, Holding Time: 15 Minutes

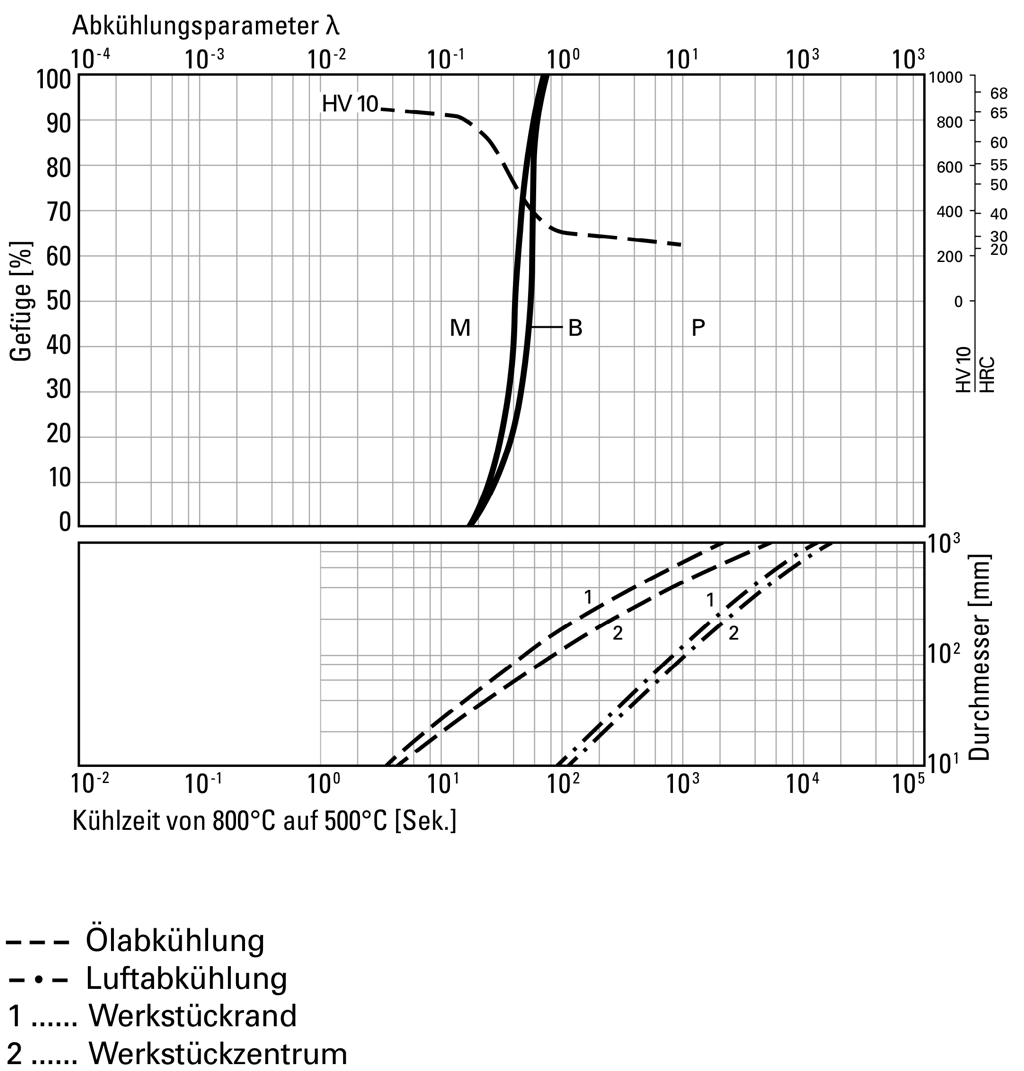

Microstructure Phase Diagram

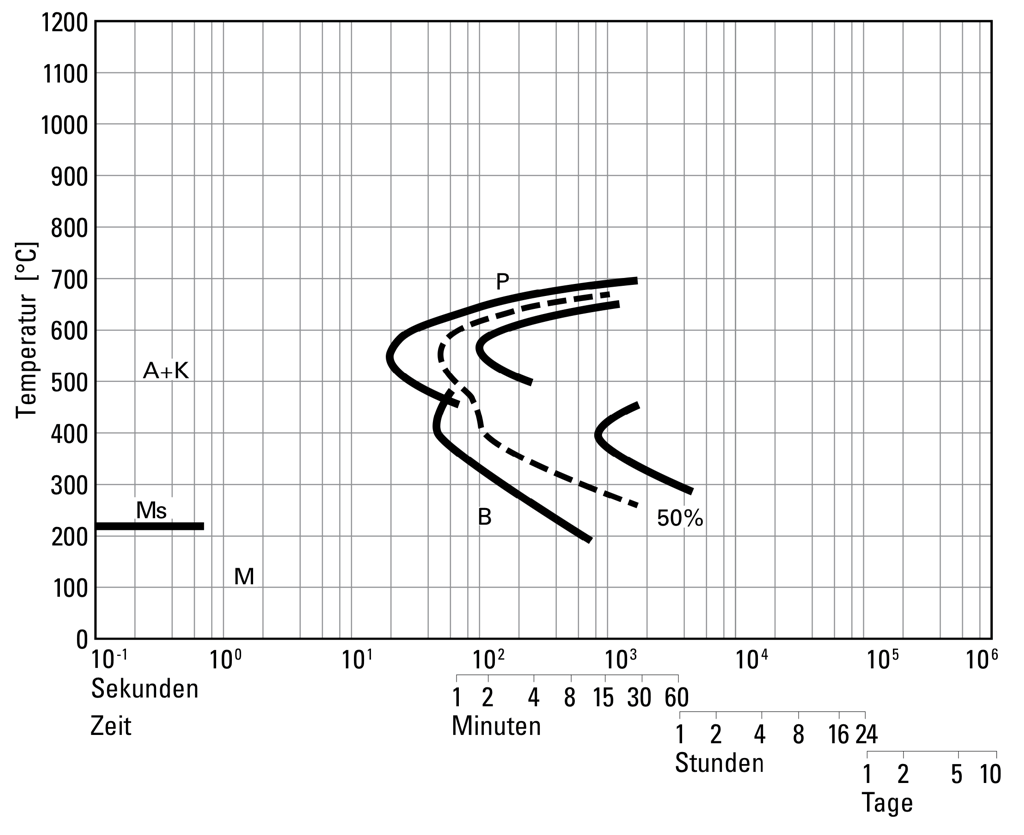

Isothermal Time Temperature Transformation Diagram

Austenitization Temperature: 820°C, Holding Time: 15 Minutes

Dependency of Core Hardness and Effective Hardening Depth on Workpiece Diameter.

Attention please!

Some features of our webshop are not supported by your current browser version.

We recommend updating your browser or using a different browser.